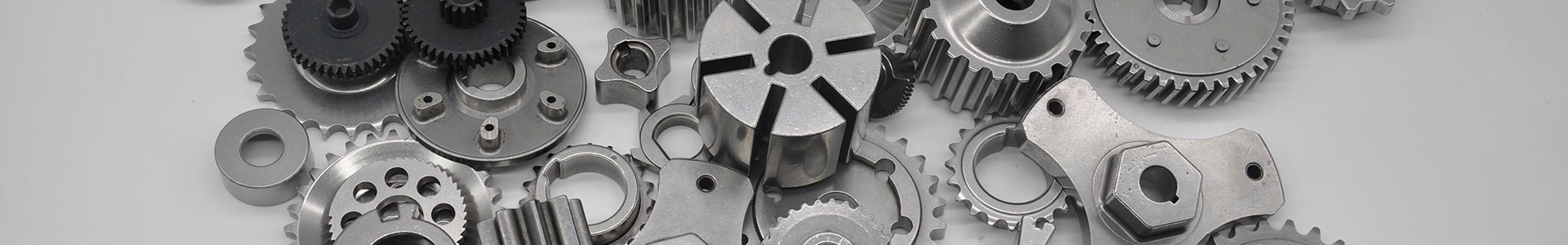

Factory customized powder metal VVT stator and rotor for automobile engine parts,used in the 1.4L engine. This part is made of modified Fe-Cu powder metallurgy material, the complex shape of the parts to form a density of 7.0g / cm3.VVT stator is characterized by five complex shape of the center hole, the pulley and VVT shell implementation integrated design. Very narrow tolerances help to minimize any oil leakage between adjacent pressurized compartments. Powder metallurgy stators help to reduce fuel consumption and the formation of exhaust gases, as well as to improve the engine’s operating performance, especially at low speed torque.

点击空白处返回

![]()

Factory Customized Powder Metal VVT Statorand Rotor For Automobile Engine Parts

Brand: OEM

Certification: ISO9001/TS16949

Country of origin: China

density of 7.0g / cm3,OEM sintered parts, engine part,Iron/copper/steel/OEM,MATERIAL:MPIF 35, DIN 30910, JIS Z2550,Surface treatment:

High frequency quenching ,oil impregnation,Processing:

Sintering - Powder Metallurgy, Hardness: HRC 30-50

3. Accuracy :±0.01 mm

4.No crumbling ,cracks ,burrs ,metal pitting and other defects

5.high productivity ,cost-efficient ,energy saving

Minimum order quantity: 10000pcs

Price: 5-10dollars

Payment method: TT/LC

Supply capacity: 200000PCS/MONTH

Delivery period: 15-30days

standard packaging:customized/PE bag+carton+wooden pallet

Certification: ISO9001/TS16949

Country of origin: China

density of 7.0g / cm3,OEM sintered parts, engine part,Iron/copper/steel/OEM,MATERIAL:MPIF 35, DIN 30910, JIS Z2550,Surface treatment:

High frequency quenching ,oil impregnation,Processing:

Sintering - Powder Metallurgy, Hardness: HRC 30-50

3. Accuracy :±0.01 mm

4.No crumbling ,cracks ,burrs ,metal pitting and other defects

5.high productivity ,cost-efficient ,energy saving

Minimum order quantity: 10000pcs

Price: 5-10dollars

Payment method: TT/LC

Supply capacity: 200000PCS/MONTH

Delivery period: 15-30days

standard packaging:customized/PE bag+carton+wooden pallet

- Description