Connecting Rods:

PM connecting rods are used in machinery and automotive engines due to their high strength-to-weight ratio. Powder metallurgy allows for the production of lightweight but durable components, improving fuel efficiency and reducing overall vehicle weight.

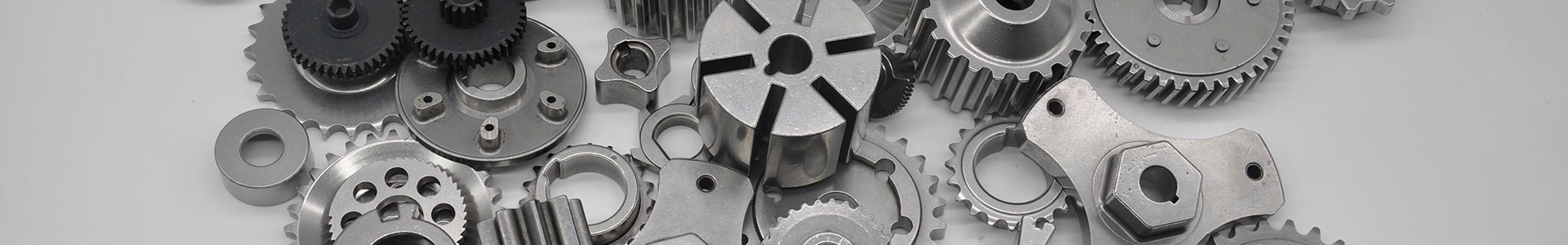

Sprockets and Pulleys:

Sprockets and pulleys manufactured through powder metallurgy are used in machinery for power transmission. Their wear resistance and ability to maintain dimensional stability under load make them ideal for use in engines, conveyor systems, and industrial machinery.

Clutch Components:

In automotive and industrial machinery, PM clutch components are used for their high precision and ability to withstand repetitive stress. The PM process allows for tight tolerance control and the integration of complex shapes, reducing the need for machining.

Structural Brackets and Housings:

Machinery often requires strong yet lightweight brackets, housings, and supports. PM structural parts provide excellent strength while maintaining a cost-effective production process. These components can be found in various applications, from automotive systems to agricultural and construction equipment.