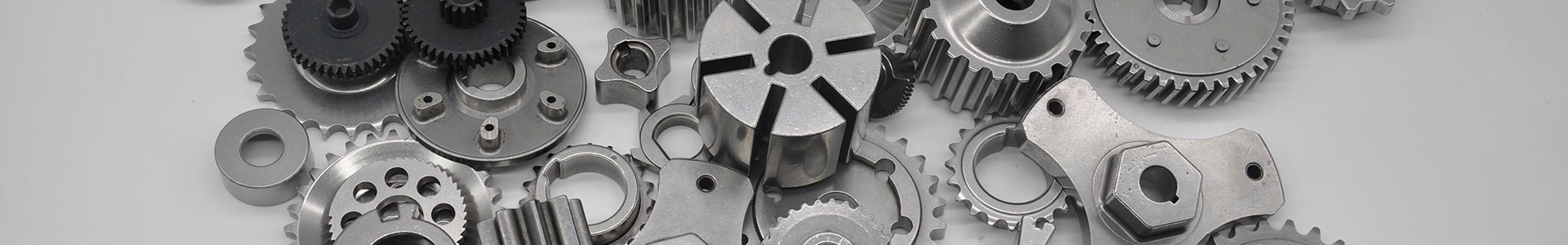

The powder metallurgy process can now produce many types of gears: spur gears, helical gears, double gears, belt pulleys, bevel gears, face gears, straight bevel gears, spiral bevel gears and hypoid gears. Users usually choose powder metallurgy to manufacture gears because of its multiple technological advantages:

•Provide true involute tooth profile and complete fillet radius.

•Easy to install weight-reducing holes, thereby reducing the weight of parts.

• Because the material is porous, it helps to quiet the running mechanism (looseness will attenuate the sound) and make it self-lubricating (through oil immersion).

•The gear can be combined with other mechanical elements (such as cams, ratchets, drive lugs or other gears) into one piece.

• It is possible to manufacture a gear with a radius at a blind corner, thereby eliminating the undercut release required for cutting gears and providing additional radius strength.

•Almost no or no machining is required, and the material utilization rate is close to 100%.

• Gears with integrally mounted shafts can be produced, either as short trunnions or by bonding machined steel shafts to the gears during the sintering process.