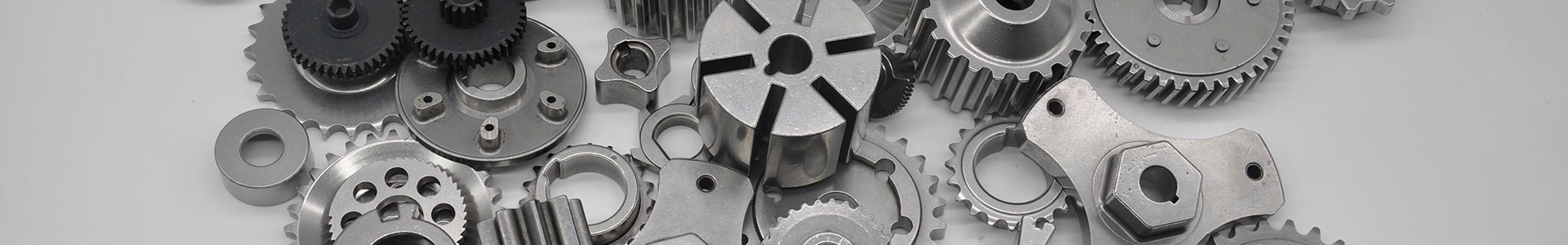

How to improve the strength and wear resistance of powder metallurgy gears

In order to improve the strength and wear resistance of powder metallurgy gears, we usually need to add post-processing engineering after the powder metallurgy gears are sintered to improve their performance. For example, in the post-treatment of powder metallurgy gears, engineers of powder metallurgy gear manufacturers generally use surface water vapor treatment and carburizing treatment to increase the wear…