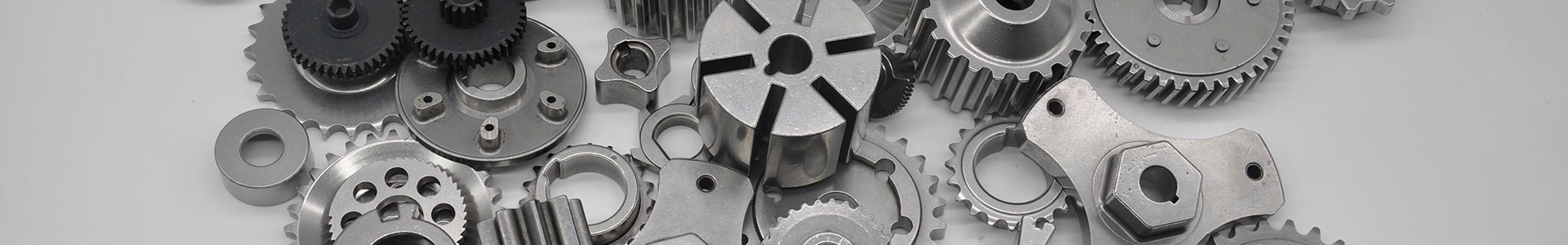

Material: stainlees steel gears /SMF5040/5030/FC0208/MPIF 35, DIN 30910

Density:6.0-7.2g/cm³

Hardness: HRA45-75

The advantages of powder metallurgy gears are as follows:

- One-time molding: low cost, high production efficiency, one-time molding and finishing process, no need to reprocess gear teeth after molding. It can fully meet the dimensional accuracy requirements, especially the tooth shape accuracy.

- Lubrication-free parts: Due to the processing characteristics of Powdered Metal Gears, oil-containing parts can be made to form lubrication-free parts.

- High utilization rate of resources: There is no waste in the gear forming process, which is the best for the utilization of steel resources.

- The repeatability of sintered gears is very good. Because powder metallurgy gears are formed by pressing molds, under normal conditions of use, a pair of molds can press tens of thousands to hundreds of thousands of gear blanks.

Welcome to send us the drawing for custom: Gears, sun gears, Double gears, DC motor gears, Gearbox parts, Planetary gears, mini motor gears, bevel gears, powdered metal gears, Helical gears, powder metal gears, sintered metal, sintered parts, sintered gears