- Density: 5.9~7.2 according to material and your required

- Tolerance: ±0.01mm or as your request

- Size:According to your drawing(stp,dwg,igs,pdf),or sample,provide custom service

- Sample Available

- Application

- Production Process: Powder metallurgy

- Material: Sintered iron , sintered Stainless Steel, Stainless steel,Iron,Brass,Copper,Aluminum

- Feature: High strength, high precision

- Usage: Medical apparatus and instruments,Power tool,Automobile industry,Home appliances etc… like: Toy train,sports car,Electric tool parts,Lock parts

- Supply Ability: 600000 Piece Monthly

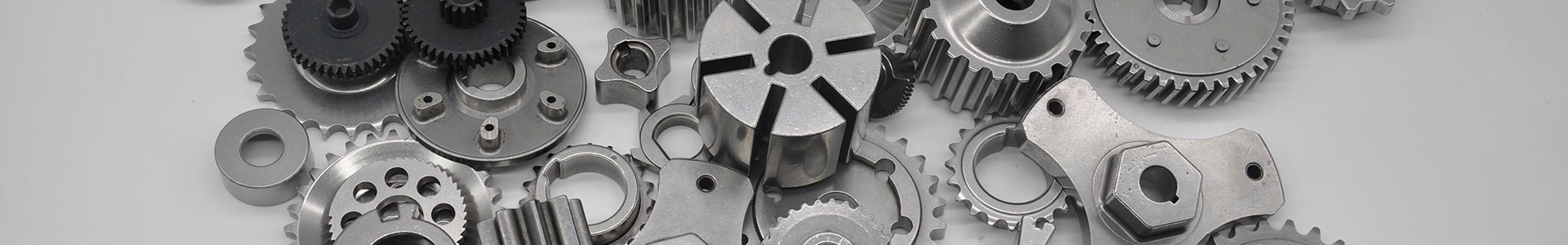

planetary gears set

We are manufacturer and exporter of sintered metal parts since 2014, mainly produce small spur gears,bevel gears,helical gears,pinion gear wheel,metal bushing, miniature planetary gear set and other sintered structural metal components,any metal parts can be customized.according to your drawing.

Powder metallurgy(PM) is a state of the art metal-forming process used to produce net-shape components,which typically uses more than 97% of the starting raw material in the finished part.

Advantage of planetary gear systems

- The more the planets in the system, the greater the load ability, and the higher the torque density

- Speed Reduction

- Obtain high power density

- Large reduction in small volume

- Pure torsional reactions, and multiple shafting

- Creates greater stability

- The more the planets in the system, the greater the load ability, and the higher the torque density